Page 1 of 1

2011 Jeep Grand Cherokee Rotor Removal

Posted: Mon May 01, 2017 1:38 pm

by motley06

Just had a 2011 Jeep Grand Cherokee Laredo 3.6 come in the shop. We found the labor guide shows .8 to remove the front rotors EACH. We generally just use rotor removal as a guide for machining rotors. However, if we used the guide in this instance, we'd be getting close to $200 after hazmat/shop supplies/taxes/etc. Is this correct, or a misprint? I would be more inclined to believe .8 for both rotors, not each. I checked the repair info and it looks pretty straight forward, but I've never done brakes on a Jeep before...

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Mon May 01, 2017 2:31 pm

by brianp87

I would charge 2 hours to replace the pads, clean and lubricate slides and resurface the rotors on the vehicle.

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Tue May 02, 2017 4:57 am

by steven kiser

Is this the labor as an add on or stand alone?

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Tue May 02, 2017 7:30 am

by motley06

stand alone. 1.6 just to remove rotors seems excessive to me

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Tue May 02, 2017 12:34 pm

by liljoe

motley06 wrote:stand alone. 1.6 just to remove rotors seems excessive to me

I have seen this on these as well. I just charge 1.0 for rotor R&R, which is normal for a hat style rotor with no caliper bracket in the way.....

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Wed May 03, 2017 2:08 am

by steven kiser

Not sure but doesn't this also include dealing with rotor run out. I remember running into a lot of run out issues where the rotors would have to be secured to the hub and run out checked. I would take 5 run out readings on each before picking a mounting location then mark it for future ease if I needed to remove it. I work on a fleet of delivery Jeeps and if this wasn't done it would be back in about two thousand miles with a pulsation. This issue may or may not include this year but even now when I'm doing brakes on a Jeep I always check rotor run out. The degree of issues have dropped way down but on occasion I'll run into an issue where the machine surface on the hub will be out and need some TLC to guarantee a quality brake job.

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Wed May 03, 2017 3:55 am

by ricmorin

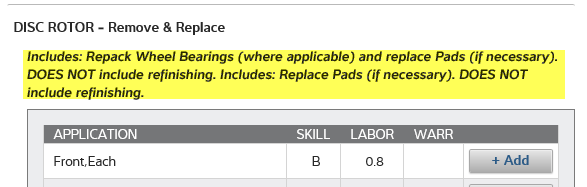

Looks like the .8 includes more than just remove and replace.

- rotor.png (21.59 KiB) Viewed 6514 times

Remember, it's only a guide.

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Wed May 03, 2017 5:04 am

by motley06

Yes, only a guide. But when it seems like there should be a correction made, I feel like someone should bring it up. It's difficult for my SA to know if it's a 'hat style' rotor or not. It would be nice if he didn't have to look at every car to see if the guide is correct or not

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Thu May 04, 2017 7:58 am

by liljoe

ricmorin wrote:Looks like the .8 includes more than just remove and replace.

rotor.png

Remember, it's only a guide.

Had a customer come back the day after I replaced a wheel bearing on the rear of some late model GM car, don't remember what kind. He was all kinds of upset cause he said I "misled" him on the invoice cause the standard notes that the guide puts on the invoice state that it includes packing the bearings where applicable and he knew that it was a sealed bearing assembly and he felt all kids of cheated. He was fine with price and work performed till he noticed that standard note. The words where applicable didn't seem to resonate with him at all.....

Never could get him to say what would satisfy him.....

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Thu May 04, 2017 8:01 am

by ricmorin

Good point. I always remove that stuff.

Re: 2011 Jeep Grand Cherokee Rotor Removal

Posted: Fri May 05, 2017 2:32 am

by steven kiser

I'm extremely careful about what I allow to be printed on the repair order. I'm constantly removing and or rewriting any transferred information. I have my work order's setup so no part numbers are on them and on occasion need to explain if there were numbers included they would be in house tracking codes that may cause confusion if they were to be used as a guide by anyone else.

Now to return to the disc rotor time guide. I've rarely seen a rotor on a Jeep that just pops right off unless it's one we've worked on before. When we remove one for any reason we use a lubricant on the hub face and center race (where rotor center rides) to make removal so much simpler in the future. Some rotors, maybe not Jeeps, with deep hats are like the old composite rotors from the 70's. If any force was used in removing them you should have tossed them. In my shop the brake lathe is rarely used since many of the vehicles we work on come in with pulsations so bad at high speeds to machine it out would exceed the minimum requirement or they are on a vehicle I just refuse to do anything but replace, scored to deep, polished with rust pockets under the surface, victims of a previous pad slap and sometimes even cheaper to replace for the customer. A long while ago I put everything I could think of regarding machining vs replacing on paper. This included cutting tips, tech time vs machining profit, time machining and then needing to replace and since I only replaced in pairs a guess on how many times it was the second on the lathe, customer complains and comebacks where we needed to machine again or replace at no additional cost to customer, upgrades to lath such as new cones, collars, inserts, silencing straps and tension pucks. Considering it would take a minimum of two rough cuts and the final with a 5 - 10% chance of it singing forcing a recut at a higher / lower rotation along with a faster / slower cut speed it began to take enough time to effect the productivity of the shop. By backing off on the machining the time on was cut in half, comebacks dropped, productivity increased as well as upsells more than enough to cover any profit loss by not machining. For larger applications or vehicles where the front bearing needs to be split I have and still use an on vehicle brake lathe. I occasionally use it to remove the run out on Jeeps and occasionally other vehicles. The days of having to machine replacement drums and rotors has long past so we just R&R and have less than a 2% return. Since the days of paying grease monkeys to work on vehicles is long gone and a tech's pay today is anywhere between 20 and 40 dollars an hour I've found in the long run it's costing me money to machine. Another point then I'm done is for some reason the brake jobs come in waves. I may not do one for a week then the in the next week I'll do three or four a day for three days and that would mean a line at the lathe and at least two bays tied up, two techs taking twice as long, and a water pump that needs replacing, a flashing check engine light on an Audi, and a Ford Explorer that needs ball Joints. That's how it is a my shop.