Page 1 of 1

2006 Hyundai Santa Fe 2.7L - Alt Replacement Time?

Posted: Mon Feb 29, 2016 11:21 am

by Sauvageaus

Came in for battery/alternator issue. Tested everything and needed an Alternator. Wrote everything up parts and labor. Labor time showed .8, well my dad comes back in and finds out he needs to remove the axle to get to a bolt, can't get it out without moving the axle. So is there a different way on doing this from future? Or should there be a combination having added the axle?

Re: 2006 Hyundai Santa Fe 2.7L V6

Posted: Mon Feb 29, 2016 11:28 am

by ricmorin

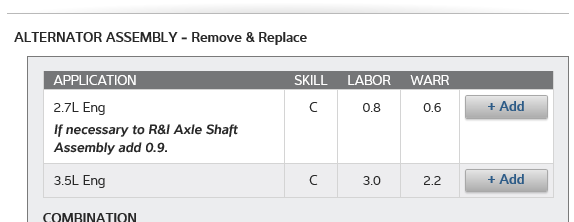

I looked this up in ProDemand and got this.....

- alternator.png (17.99 KiB) Viewed 3692 times

Showing to add .9 IF you need to remove axle.

Re: 2006 Hyundai Santa Fe 2.7L V6

Posted: Mon Feb 29, 2016 11:32 am

by Sauvageaus

ricmorin wrote:I looked this up in ProDemand and got this.....

alternator.png

Showing to add .9 IF you need to remove axle.

That's really odd, we thought we saw it in there before and I looked again and for whatever reason didn't see that in there (must of been blinded) but it is also in Estimator in Mitchell SE.

Re: 2006 Hyundai Santa Fe 2.7L V6

Posted: Mon Feb 29, 2016 11:34 am

by Sauvageaus

ricmorin wrote:I looked this up in ProDemand and got this.....

alternator.png

Showing to add .9 IF you need to remove axle.

Thanks Ric for helping, not sure why we couldn't see it the 2nd time.

Re: 2006 Hyundai Santa Fe 2.7L - Alt Replacement Time?

Posted: Tue Mar 01, 2016 2:29 am

by steven kiser

I come up with 1.7. I got stung with a labor issue like this before. Learning the hard way in some instances is the best way. On some applications I look at the labor time and then look at the tech information sheet to see what has to be done to do the job. A few times I caught issues involving manufacturers date as well as option issues. I also check it against another labor guide. I have three guides I use. Mitchell is my manager system and primary shop system. I back that up with All Data. Some techs have no use for All Data but I've been using since the mid 90's and it's second nature to me. The third system I use when working on vehicles 10 years old or older is Real Time. It takes into consideration all issues age related with it's time guide. In the past five to 10 years I've learned that paying close attention to labor, part, core, and defects have become priority. The part supply businesses in my area have one maybe two knowledgeable counter people and the rest of the employees are drivers and shelf stockers. My defects and returns have been credited as cores, incorrect parts are picked off of shelf and added to a job box etc. At one time I made my money with a wrench, today I need to use a key board to insure I make it. Sorry for the run on but this is just one part of an extremely important issue.